Business (Painting Equipment)

Purpose of electro deposition equipment

Electro deposition equipment is for primer coating of surface and complex parts of metallic products.

It is also applied to electronic products as well as car body painting line and car part line.

Purpose of using electro deposition equipment is for fast primer painting and for painting of small and deep spaces and surfaces that are hard to reach.

It is also applied to electronic products as well as car body painting line and car part line.

Purpose of using electro deposition equipment is for fast primer painting and for painting of small and deep spaces and surfaces that are hard to reach.

Electro deposition painting method

Electro deposition painting is to deposit the painted object into the paint and apply direct current and the equipment can adjust painting thickness according to the voltage.

The facility operates by automated system and uses high pressure voltage.

The facility operates by automated system and uses high pressure voltage.

Strengths of electro deposition paint

For electro deposition, water soluble paint is generally used, therefore less pinhole or sagging occurs compared to organic paint and the setting time is short.

It is low pollution paint and is treatable in waste water treatment.

It is low pollution paint and is treatable in waste water treatment.

Strengths of electro deposition painting

Electro deposition is suitable for mass production and convenient for automation.

Painting surface is clean and the painted film is strong after drying.

It minimizes paint consumption and paint recovery from multi-process is available.

Painting surface is clean and the painted film is strong after drying.

It minimizes paint consumption and paint recovery from multi-process is available.

Electro deposition types

Electro deposition is generally divided into 2 types: Anion and Cation type.

- Anion electro deposition painting : It applies anode to the painted object.

- Cation electro deposition painting : It applies cathode to the painted object.

- Anion electro deposition painting : It applies anode to the painted object.

- Cation electro deposition painting : It applies cathode to the painted object.

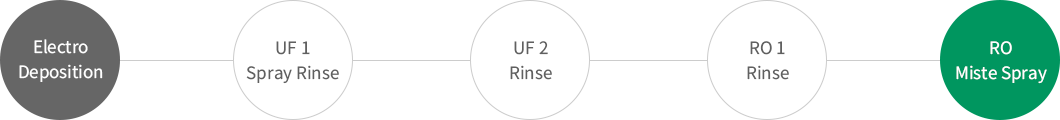

Electro deposition painting process

Organization of electro deposition equipment

- Main composition: Electro deposition tank, chamber, current system, paint circulation system.

- Equipments: Paint cooling system, DC voltage system, transfer liquid circulation system, paint dump tank, paint supply system.

- Equipments: Paint cooling system, DC voltage system, transfer liquid circulation system, paint dump tank, paint supply system.

Automated painting system for dipping

Paint circulation, filtering, paint cooling system

CEO : Kang Dahyeon

CEO : Kang Dahyeon